1.Shot Blasting for Steel Pipe Coatings |

|

|

|

Normally Shot Blasting is required prior to galvanizing, painting, or applying any type of coating to pipe, especially for exterior 3LPE, 3LPP and FBE Coating, Interior FBE or Liquid Epoxy Primer Coating. It will remove the thin rust preventive coat from the pipe that was applied at time of manufacture. It produces quite a bit of metal dust, and the process wears down the abrasive media. These type products are captured by dust collectors and don't need special treating processes or environmental precautions. This gives blast cleaning an edge over some other prefinishing treatments, such as pickling (acid cleaning), which is inherently corrosive and requires special waste treatment. |

2.Precision Pipe Cutting |

|

|

|

We offer precision cutting on lengths of pipe ranging from 2 inches to 60 feet, and diameters from 2" thru 48". The type of cutting used depends on both the size of the pipe and the required precision. The tolerance ranges from 1/8" thru 1/64". |

3.Custom Pipe Fabrication |

|

|

LK Steel Pipe offers a wide variety of custom pipe fabrication services. We can manufacture the customized pipe or pipe spools for the petrochemical, oil and gas sectors according to our customers' drawing requirements. The spool is an assembly of cut-to-length steel pipes, elbows, tees, reducers, cross, flanges, etc. |

4.Cut and Roll Grooving for Standard and Line Pipe |

|

|

|

LK Steel Pipe provides both Cut Grooving and Roll Grooving. Cut and roll grooving can be done in any style according to industry standards. It can be applied to any length of pipe ranging from 1"-48" diameters. These grooved pipes are widely used in fire fighting systems, the groove is used for connecting two pipes together with grooved fittings. |

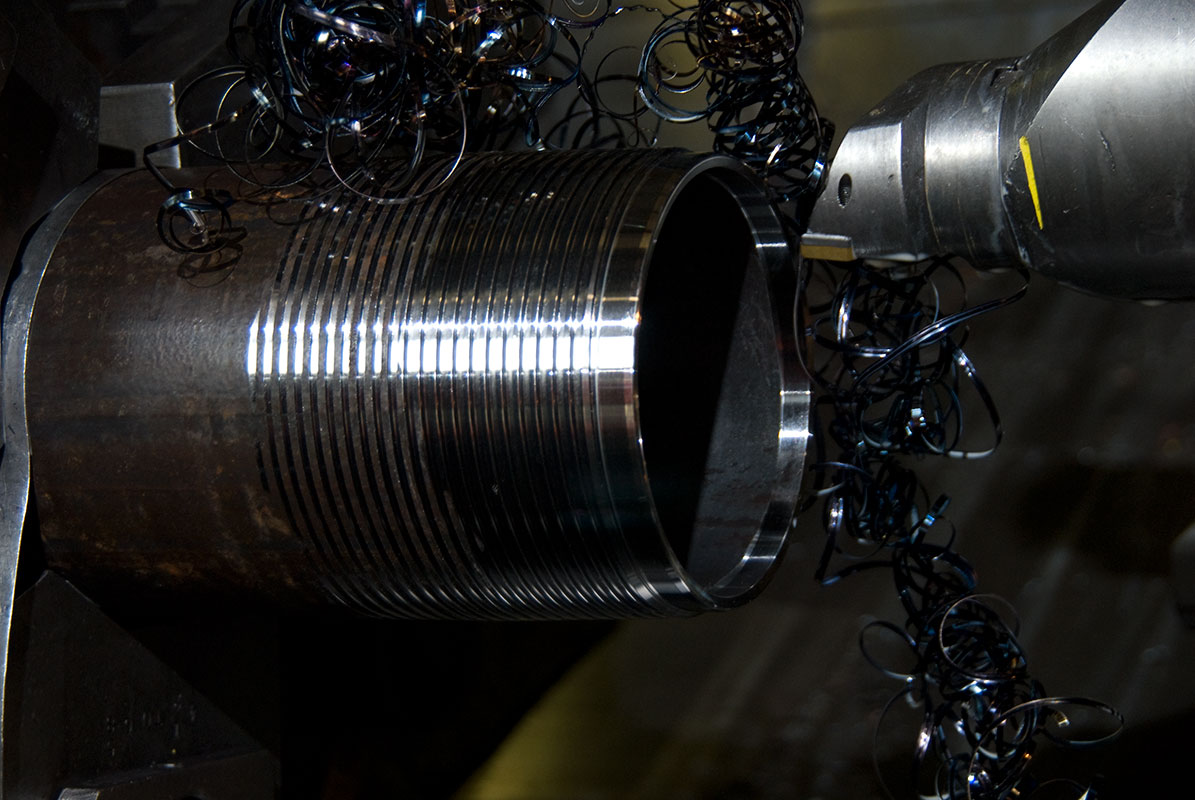

5.Pipe Threading |

|

|

|

Threaded pipes can provide an effective seal for pipes transporting liquids, gases, steam, and hydraulic fluid. We thread any length of pipe in diameters ranging from 1/8" thru 20". Tapers available are NPT*, NPS*, 3/16" Peerless, and 8 round taper. (See fabrication services page for larger diameters) *National Pipe Thread is a U.S. standard for tapered (NPT) or straight (NPS) threads used to join pipes and fittings. ANSI/ASME standard B1.20.1 covers threads of 60-degree form with flat crests and roots in sizes from 1/16 inch to 24 inch Nominal Pipe Size. The taper rate for all NPT threads is 1/16 (3/4 inch per foot) measured by the change of diameter (of the pipe thread) over distance. The taper divided by a center line yields an angle 1° 47' 24" or 1.7899° as measured from the center axis. |

6.Pipe Beveling |

|

|

|

We can apply any type of Bevel to any degree required. Beveling can applied to the face of any size or diameter of pipe. Usually the pipes for oil and gas or any other fluid conveyance need to be bevelled both welding ends to an angle of 30°, +5°, -0°, with a root face of 1/16", +/- 1/32". The bevel shall form a V groove with an included angle of 60°+10/-0. The root opening shall be 1/16", +/- 1/32" according to ANSI B16.25. |